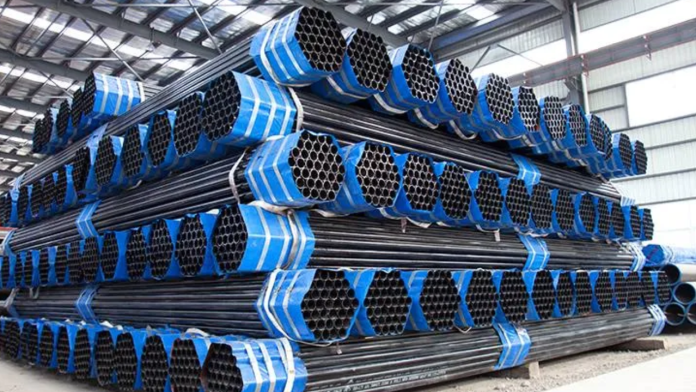

A significant advancement in industrial plumbing, seamless pipes are identified by their seamless, weld-free construction. Whether made of stainless steel, carbon steel, or specialty alloys, seamless pipes are renowned for their strength, consistency, and ability to withstand corrosion. Precision steps in the production process include creating the billet, heating it, piercing it, sizing it, and finishing it.

Because of this careful process, seamless pipes have consistent wall thickness and diameter, which makes them perfect for applications that demand dependability, such as those in the construction, automotive, and oil and gas sectors. The structural integrity of seamless pipes is improved by the lack of welds, making them resistant to high pressures and severe environments click to visit for additional information on seamless steel pipes.

Seamless Steel Pipe Is Used

Because of its special qualities and benefits, seamless steel pipes are employed in a wide range of sectors and applications. Here are a few typical applications for seamless steel pipes:

Oil and Gas Industry:

Crude oil, natural gas, and other hydrocarbons are transported by a vast network of seamless steel pipes in this industry. These qualities of durability, resistance to high pressure, and corrosion resistance make them perfect for pipelines that travel large distances, frequently across difficult terrain.

Building and Infrastructure:

Seamless steel pipes are used in many different structural components, including foundations, beams, and columns, in the building sector. The stability and longevity of infrastructure projects and buildings are facilitated by their strength and dependability. Seamless pipes are also utilized in construction projects’ piling for deep foundation systems.

Automotive Industry:

The production of automotive components requires seamless steel pipes. Their great strength, heat resistance, and toughness make them a popular choice for manufacturing exhaust systems, chassis, and other vital components.

Power Generating:

The transportation of steam and other fluids in power plants is a critical function of seamless steel pipes in the power-generating industry. They are used in the building of heat exchangers, super heaters, and boilers, which improves the dependability and efficiency of power-producing facilities.

Aerospace Industry:

The manufacturing of airplane components, such as fuel lines, hydraulic systems, and structural elements, depends on seamless steel pipes. Seamless pipes’ robustness and light weight make them particularly useful in aviation applications.

Chemical and Petrochemical Industries:

Corrosive materials are transported via seamless steel pipes, which are widely utilized in chemical and petrochemical processing facilities. They can handle a range of fluids and gases in these industries thanks to their high-pressure capabilities and resilience to chemical corrosion.

Water and Sewerage Systems:

Because of its longevity and resistance to corrosion, seamless steel pipes are essential components of water and sewage systems. These pipes are essential components of the infrastructure of cities because they provide the timely delivery of clean water and the effective disposal of wastewater. Their durability and resiliency address the basic demands of communities all over the world by considerably enhancing the sustainability and efficacy of sewage and water supply systems.

Mining and Exploration:

Seamless steel pipes are essential in mining and exploration for material conveyance, fluid transportation, and drilling activities. These abrasion-resistant and long-lasting pipes endure the severe circumstances found in mining sites, guaranteeing dependable and effective extraction procedures. Their support of the fundamental operations of the mining and exploration industry is demonstrated by their participation in resource extraction.

Applications for the Marine Environment:

In shipbuilding and marine engineering, seamless steel pipes are employed for a variety of tasks, such as creating offshore platforms, ship pipelines, and other marine constructions. The durability and safety of marine infrastructure greatly depend on its capacity to endure hostile marine environments.

Renewable Energy Projects:

Seamless steel pipes are used in the construction of support structures and transmission systems in the renewable energy industry, which includes wind and solar power projects. These pipes offer the stability and strength required to resist environmental factors.

Bottom Lines

Throughout many different sectors, seamless steel pipes are essential for the effective movement of fluids, the maintenance of structural integrity, and the improvement of crucial system dependability. They are a vital component of contemporary infrastructure, guaranteeing the continuous development and sustainability of numerous industries across the globe because of their strength, resistance to corrosion, and adaptability.